Leather and sustainability

There’s a lot of talk about sustainability in the media, and amongst shoe brands at the moment. I recently had the opportunity to attend a conference on Leather and Sustainability in Retail, run by Eurofins BLC. I wanted to find out how sustainable or unsustainable leather and its alternatives are.

The speakers at this conference were all industry experts. Although I can’t share all of the information I heard during this fascinating afternoon, here are 8 facts I found most interesting or surprising.

1. Not all hides are used

Global supply of animal hides is currently outstripping demand. This is due to increased meat consumption by economically fast-growing countries, and lower demand for leather.

This has caused a dramatic decrease in the price of finished leather, which is benefiting footwear producers, brands and retailers. The bad news is that the market for some of the lower grade hides has disappeared. Producers are simply disposing of these animal skins, which is a shameful waste.

Whilst some consumers have chosen to stop buying animal products for ethical reasons, this is contributing to waste in the livestock rearing industry. The animals whose skins are being wasted have died just for their meat. These animal skins are going to landfill or being burnt, neither of which is beneficial for the environment.

Of course if everyone around the world ate less meat, there would be a reduction in waste hides and leather prices would rise again.

2. Leather is a by-product

I used to wonder whether leather really is a by-product of the meat industry. Is consumption of leather or meat the main commercial reason for raising livestock?

Although the meat and leather industries are symbiotic, I learnt that most of the value of a cow is in the meat. In fact Peter Hughes from Eurofins BLC told the delegates that 93% of the value of a cow is in its meat. The hide value is only 3% of the animal’s monetary value.

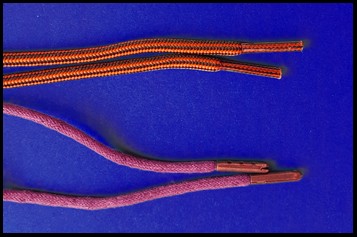

To break an average beef cow down by mass:

- 7% is allocated to the hide

- 49% is meat and edible offal

- 22% is split between animal feed, food grade bones and food grade fat

- 22% is unusable waste

3. Young people don’t mend

I get very attached to my footwear, and if I can make a beloved pair last longer, I will. I was always taught to look after my belongings, and as a child I was made to polish my shoes once a fortnight. Fixing things when they broke, and using spare parts was instilled in my generation by our post-war parents.

A survey conducted by Ecotextile News, found that under 25s don’t have that make do and mend attitude. In fact, 43% of respondents in that age bracket said they would throw away a pair of shoes because of a missing lace or broken zip.

This made me determined to ensure my little boy sees me fixing toys and clothes. I’ll also try to teach him these practical skills. What else do you think we can do to encourage the younger generations to extend the life of their belongings? What can your business do? Will you offer a repair service to your consumers? Please let me know in the comments.

4. Sustainability definition is unclear

There’s a lack of knowledge amongst young people about what improving the environmental impact of industry (or making it “sustainable”) actually entails.

Michael Costello from Stahl shared the findings of a study and education exercise conducted by renewable energy company Masdar. The research found that 18-25 year olds (Generation Z) thought climate change should be a top priority on the global agenda.

Although this generation are well aware of the imperative for improving our impact on the environment, there are gaps in their knowledge.

Michael told us about a group of Global Luxury and Management graduate students from NCSU and SKEMA educational institutions. When these students were asked to define sustainability, they thought about products on a superficial level. Predominantly considering the materials used in manufacture, rather than the end-to-end production process. There was no consideration of the environmental and human impact of discharge of harmful chemicals and waste. Nor did they consider water consumption, air pollution, or whether products could be recycled.

Through Stahl’s education program, these students gained a greater understanding of the impact of the industry they’re entering. Stacey Dooley’s “Fashion’s Dirty Secrets” documentary for the BBC has been widely watched in the UK. Consumers and industry professionals are becoming more knowledgeable, and it’s up to us to maintain that momentum.

5. Synthetic isn’t better than leather

Ethical sourcing, sustainability and environmental credentials, and products which aren’t detrimental to animal welfare are often grouped together and assumed to be interlinked. Synthetic materials used to make footwear are considered by some consumers to be “good”, and leather to be “bad”. While the media often criticise the leather industry, the growth in people making a choice to adopt a vegan lifestyle has increased demand for synthetic footwear.

Peter Hughes from Eurofins BLC enlightened us about the environmental impact of PU (polyurethane) which is the most commonly used synthetic alternative to leather for footwear.

DMF (Dimethylformamide) is used in the production of PU material for footwear. DMF has been associated with toxicity to humans. PU doesn’t easily biodegrade (500 yrs+), conversely its lifespan in wear can be shorter than leather. PU is much more difficult to recycle and upcycle than leather, and burning PU waste can release harmful carbon monoxide. It seems there are many ways in which PU is less sustainable than leather.

Whilst Peter enlightened us about the benefits of synthetic materials as substitutes for leather, I was shocked by the harm their use can cause.

On a more positive note, there are companies such as Piñatex manufacturer Ananas Anam, and Modern Meadow, who are producing, or working towards more environmentally beneficial shoe materials.

6. Not all “skin” is made from animals

Susan Schofer from Modern Meadow explained some of the groundbreaking activities being carried out by her company. Very simply put, they’re harnessing the power of yeast to grow collagen proteins (the building block for all animal skins). This enables them to produce high-performing materials like Zoa™ for footwear and apparel, completely animal-free.

If you’re interested in learning more about this company’s fusion of design, biology and material science, then I’d recommend having a look at their website.

7. It’s time to be nosey

Robert Perkins – Chief Operating Officer at Hotter Shoes – enlightened us about his company’s journey towards achieving far greater control of their supply chain. He explained how reducing their supplier count, consolidating the variety of leathers they use, and purchasing raw materials directly from source has enabled this change.

The top tip Robert shared was to visit all of your suppliers. Don’t just make a flying visit for a few hours, but really get to know them. Stay overnight, and eat with the owners. The more time you spend with a supplier, the better you’ll understand if their business practices align with what you expect of them.

8. You’re not on your own

There are advisory bodies and organisations who can help you understand the impact the materials you use, and chemicals used in production of your products will have on the environment and animal welfare.

Here are some of the bodies and standards I heard about at the conference:

- Eurofins BLC – leather testing and technology centre

- Textile Exchange – driving industry transformation in preferred fibres

- Leather Working Group – the online resource for the leather industry

- Better Cotton Initiative – making global cotton production better

- Responsible Wool Standard – voluntary global standard that addresses the welfare of sheep and the land they graze on

- ZDHC – leading the textile, leather and footwear industries towards zero discharge of hazardous chemicals

- The Sauer Report – the world’s leading hides and skins pricing platform and provider of market trends and information on the leather industry

- Chem-Map – ZDHC approved MRSL (manufacturing restricted substances list) chemical verification systems

- Stahl Campus – providing training on leather and performance coatings to improve supply chain transparency

What now?

Sustainability is not a simple or clear-cut standard that brands and retailers can easily achieve. There are numerous variables involved in the materials and components we use, manufacturing processes of footwear, the packaging we choose, and the freight methods we adopt. There’s no simple answer to getting it right.

So what can you do? You can get informed. Find out where your materials and components come from, and exactly how they’re manufactured. Analyse all of your suppliers. You can even send them surveys as Hotter Shoes did. Learn as much as you can about the footwear you’re creating, and you’ll have a chance of making better sourcing decisions for our planet.

Make sure any claims you make about your company and products stand up to scrutiny. I can help you work out how to avoid the potential “greenwashing” pitfalls. Let’s have a chat about creating your brand’s sustainability strategy.

Thank you Susannah for the informative article; I had not given too much thought too the treatments of the leathers and chemicals used, hence the pollution to the environment. I will make it a point to investigate further. We have an obligation whilst using products, such as leather or any other materials, to educate ourselves on the potential „side effects“ to our surroundings. Great information!

Hi Laura,

Thanks so much for your comment. I’m so glad you found the article useful. Please do feel free to share it with your shoe contacts.

With very best wishes,

Susannah

Excellent blog Susannah. Really enjoyed reading it. You manage to present the facts in a clear and neutral way which will help people make sensible and informed judgements when sourcing materials. I totally agree, there is no simple way in getting it right.

Thank you for organising the conference which inspired this article Martin. I learnt a great deal that I’m thrilled to be able to write about, and pass on to my clients. I’m happy that you enjoyed reading the piece.

Best wishes,

Susannah

Thank you Susanah the article is great . I have very little knowledge of the leather industry. Recently I have started to work with some tanneries in developing countries. I will be very keen to speak to you .

Regards

Syed Reza

SDNR Ltd UK

Many thanks for your message Syed. I’ve sent you an email so we can arrange a call. I look forward to hearing from you.

Best wishes,

Susannah

Susannah, I also saw your excellent article on Twitter, thanks. Indeed, as Martin said, you have captured the issue in a concise and neutral way, which is not easy when the issues at hand are quite complex. Much appreciated.

Thanks very much for your comment Mike. I found your talk insightful, and was keen to communicate the elements I learnt from you and the other speakers to a wider audience. I’m glad I did justice to this multi-faceted topic.

Best wishes,

Susannah

Love this article! Samuel Hubbard Shoes offers a repair service.

Good! Well done you. More shoe brands should be taking responsibility for their own post-consumer waste. I know it’s not easy though. Would you consider sharing how you set this up with other shoe brands?

Hi there,

Its interesting to see how this develops at michele-caruso.com we are also working with sustainability.

It certainly is! Your products are simply beautiful.